advantages of rockwell hardness testing method|rockwell hardness testing machine diagram : Big box store The Importance and Benefits of Rockwell Hardness Testing. Measuring the hardness of materials is a pivotal step in understanding their suitability for various applications. One of the most recognized and widely . With that, we're introducing Microsoft Phone Link as the PC app experience, and Link to Windows as our mobile app for Android devices. A fresh new look We’ve polished the design of Phone Link on your PC by updating the app’s interface to complement Microsoft’s Windows 11 design language.

{plog:ftitle_list}

WEBShemaleHere.com is a collection of hot transgender porn videos. Explore the hottest shemale porn in various categories: Shemale Fucks Guy, Ebony, Solo, Sissy, Asian, Lesbian, Japanese, Shemale And Girl, Big Cock, Amateur, Compilation, Bbw, Small Cock, Granny, Homemade and many other. Thousands of Shemale, Ladyboy, Crossdressers .

Advantages Of Rockwell Hardness Test. 1. Versatility and Wide Applicability. 2. Quick and Efficient. 3. Ease of Use. 4. Wide Range of Hardness Scales. 5. Surface Preparation Flexibility. 6. Non-Destructive Testing. 7. Adaptability to .

The Rockwell method has the following advantages: no specimen preparation required (separation, grinding, embedding) hardness value directly readable, no optical evaluation required (measurement of diagonals as in the optical methods) The Importance and Benefits of Rockwell Hardness Testing. Measuring the hardness of materials is a pivotal step in understanding their suitability for various applications. One of the most recognized and widely . Hardness testing provides a valuable measure of a material characteristic with a number of benefits, including: An automated hardness testing machine allows hardness to be measured relatively simply. To provide .

Advantages of Rockwell Hardness Test. Typically, the Rockwell test is easy to execute and more precise than other kinds of hardness evaluations. The Rockwell test technique is used on all metals, except when the test would .

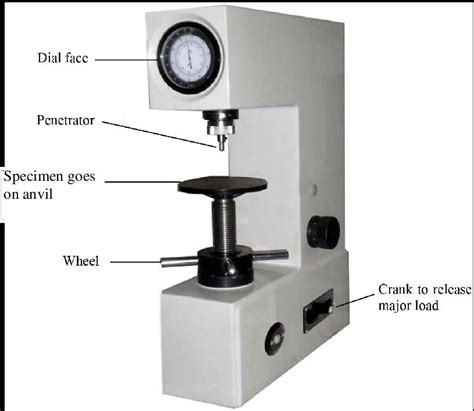

Advantages of the Rockwell Test. There are several reasons for the popularity of the Rockwell test. The test itself is very rapid. On a manually operated unit, a Rockwell test takes only five . The Rockwell Hardness Test is actually one of several tests aimed to gauge a material’s compatibility as a component to an object based on their strength and durability. The other tests in the series include the the .Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. . Knoop Hardness Each method has its advantages and limitations, and the choice of method depends on the material being tested and the .

The Rockwell hardness test is a non-destructive testing method that is used to measure the hardness of materials. . The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable .Rockwell hardness testing is measured using the Rockwell hardness scale with the method defined in ASTM E18 and BS EN ISO 6508-1. . Some of the advantages of the Rockwell hardness test include: A Simpler planning stage than the Brinell test method which requires decisions, such as the selection of the appropriate force, to be made .

The Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. . article we have put together all the information you will need to grasp the workings of the Rockwell hardness testing methods as well as its many advantages and applications. So, if you .

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test. Advantages of Rockwell Hardness Test Typically, the Rockwell test is easy to execute and more precise than other kinds of hardness evaluations. The Rockwell test technique is used on all metals, except when the test would introduce too many surface variations; when indentations would be too large; or where the sample otherwise prohibits its use.What Are the Benefits of Hardness Testing? Hardness testing offers a significant measure of material characteristics with several advantages: . Rockwell Hardness Test: This method assesses the depth of indentation caused by a specific load on the material’s surface. It’s highly versatile and straightforward, making it widely used across .Advantages of Rockwell Hardness Test: Quick and easy to perform: The Rockwell hardness test is a quick and easy method for measuring the hardness of materials. It requires minimal preparation and can be performed within a few seconds.

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .

rockwell hardness testing procedure pdf

These hardness tests can be categorized as macro and micro. All hardness testing methods lie under these categories. In this article, we will discuss hardness types, advantages, disadvantages, and applications. These things are important to understand as they have many consequences on the mechanism of indentation in the hardness testing methods.

The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. . The Rockwell hardness test's primary advantage is that you get the hardness values directly without doing the .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .The Vickers hardness test methods have the widest range of applications than any other test. It is suitable for measuring the hardness of both soft objects with the strength of 8 HV only to hard objects with a hardness of 2000 HV.

The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is measured. The total test force is applied in two stages to eliminate errors .

They have their own unique advantages and applicable scenarios. This article aims to provide an in-depth look at these two hardness testing methods. We will compare their principles, benefits, limitations, and application areas. . we .Advantages Of Rockwell Hardness Test 1. Versatility and Wide Applicability . When it comes to hardness testing, two widely used methods are the Rockwell Hardness Test and the Brinell Hardness Test. Let's explore how these . Hardness testing is a crucial aspect of metallurgy, as it provides valuable insights into a material’s mechanical properties and overall quality. There are various methods available for measuring hardness, each with its own set of advantages and limitations. In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method over . Hardness testing is an important evaluation in material science, assessing resistance to deformation and wear. Rockwell and Brinell hardness tests are among the most widely used methods in this field, each with distinct methodologies and suited to different types of materials. The Rockwell test is known for its efficiency and ease, measuring the depth of [.]

This test is considered one of the simple and quick hardness testing methods. Rockwell hardness testing is performed by comparing the penetration depth measurement of an indenter under a large load known as a major load and a smaller preload known as a minor load. . Advantages of Rockwell Hardness Testing. Hardness testing is a crucial method for evaluating the mechanical properties of materials. It helps determine a material's resistance to deformation, wear, and scratching. Among the various hardness testing methods, the Brinell and Rockwell tests are two of the most commonly used techniques. In this article, we will c Rockwell hardness test is a fast testing method found for production control, with direct reading, used primarily for metallic materials. Rockwell hardness (HR) is calculated by measuring the depth of the indentation after inserting the indenter into the sample material at a given load, which reflects the measured resistance of the metal to indentation.

In addition, the hardness value can be read with no additional optical equipment, making it one of the most common hardness testing methods. The Rockwell test is described in ASTM E18 . Knowing the advantages and disadvantages of each test is key to determining which method is the most appropriate for the material to be tested. Related Terms.The Knoop method has the following advantages. . from soft to hard, as the procedure covers the entire hardness range. There is only one type of indenter, which can be used for all Knoop methods. . (compared with the Rockwell method). The test cycle takes somewhere between 30 and 60 seconds, not including the time taken to prepare the .Rockwell hardness testing is a method of determining the relative hardness of a material. In this test, hardness is measured by determining the depth of residual penetration by a steel ball or a diamond point under load. . Some of the advantages of Rockwell testing are listed below: Simple and easy test procedure; Readings can be directly . In this article, we want to look into the four different methods of indentation hardness testing methods. Rockwell Hardness Testing. First developed over one hundred years ago, the Rockwell hardness test is a rapid hardness testing method primarily used for quality assurance and production control. It uses a diamond cone or steel ball to first .

Rockwell’s test is used for soft and medium hard materials (aluminum, soft steel, Cu alloys etc.) Advantages of Brinell and Rockwell Hardness; Advantages of Brinell’s method is the simple surface preparation and the easy measurement of the print diameter.

rockwell hardness testing procedure

1954 Volkswagen Beetle Deluxe Sedan Vehicle Information VIN: 10647070 Stock: 201014 Mileage: 6,292 Color: Stratos Silver Trans: Four-speed manual Engine: Numbers correct .

advantages of rockwell hardness testing method|rockwell hardness testing machine diagram